TO MAKE THE WORLD BETTER

Pipes Crafted From 100% Virgin Raw Materials For Superior Performance

We are a polymer pipe and fitting manufacturer focused on innovation and reliability. Located in Khordha, Odisha, our advanced facility produces 20,000 MTPA of high-quality PE pipes and is planning to establish 10,000 MT of PVC (UPVC, CPVC, OPVC) for various applications, including water supply, sewage, gas distribution, mining, and irrigation. We use 100% fit-for-purpose grade raw material, ensuring durability, flexibility, and compliance with national and international standards. Our commitment to safety and industry leadership drives us to provide cutting-edge solutions supported by a skilled professional team dedicated to excellence in production and service.

German Technology

Pipes availability - 20mm - 500mm

Certified by LRQA Group

Made from 100% pipe-grade polyethylene resins

RAREAN: Pervading Excellence Globally with INVA's Superior Performance and Unmatched Value

In Sanskrit, it means pervading or spreading throughout. This explains how RAREAN intends to spread its presence globally, similar to INVA.

INVA guarantees superior performance to provide high cost-benefit to ensure that customers’ long-term goals are addressed.

Conscientious Product Quality

State of the Art Manufacturing

Highest Dimensional Accuracy

Wide Product Range

Driven by Integrity, Innovation, and Passion: Our Core Values Guide Everything We Do

We constantly seek to explore, challenge, and improve. Our curiosity drives us to climb new heights, while our innovative spirit ensures we continuously push the boundaries of our thinking and actions.

Fueled by determination and boldness, we approach every task with enthusiasm and the confidence to challenge the status quo. Our passion is contagious, and our fearless culture empowers us to take risks and embrace change.

We stand firm on our principles, always choosing what is right over what is easy. Our decisions are guided by conscience, and we are driven not just by profit but by a purpose to improve lives and foster positive impact.

Produced

Customers

Projects

Clients Testimonials

What Our Clients Say About

Our Factorial Services

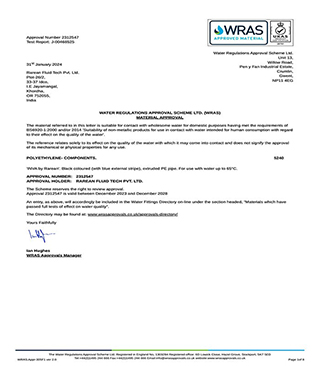

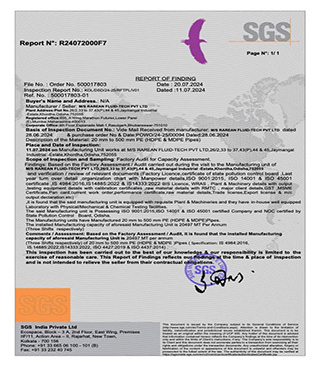

Trusted Quality: Our Product Approvals And Certifications

-

LRQA Group, certified us for ISO: 14001, ISO: 9001, and ISO: 45001

-

Product license by the Bureau of Indian Standards (BIS) for IS: 4984, IS: 14333, and IS: 14885

-

NFS approved us for WRAS

-

ISO: 4427

-

ISO: 4437

-

EN: 12201

-

ASTMD: 3035

Our

Certifications

Globally Acclaimed Pipeline Professional & Turnaround Specialist

-

With 35 years of experience in various fields, has a strong background in the Oil & Gas Pipe Industry. He was the former CEO of Welspun Corp, a leading global manufacturer, and helped it achieve a 100% growth rate.

-

Recognized by the leading business magazine, “Business World”, as the “No. 1 Most Valuable CEO” for the year 2008, in the Materials sector and “No. 5 Most Valuable CEO” in the All-Industry Basis. He was again recognised in 2009 as “No. 6 Most Valuable CEO” on an All India basis.

Trusted Worldwide: Proudly Serving a Diverse Portfolio of Domestic and Global Clients